Of all the concerns people tend to have with electric vehicles, one of the most common involves the materials necessary to make EV battery packs.

Minerals like cobalt and nickel, key components in nickel-cobalt-aluminum (NCA) batteries, are relatively scarce, leading automakers to shift away from NCA and toward lithium iron phosphate (generally referred to as LFP).

But there are supply implications with LFP, too, especially when other resources, like fertilizer and solar panel batteries, are vying for the same materials.

A newly discovered phosphate rock deposit could help resolve some of these supply anxieties for the next few decades.

A mining company called Norge Mining has located a 77.1 billion-ton cache of phosphate rock in southwest Norway, prompting experts to estimate the supply will cover EV battery, solar battery, and fertilizer needs for roughly 50 years.

Much of the world’s mined phosphate rock is used to create commercial fertilizers. Large-scale chemical processing produces orthophosphoric acid, the form of phosphate that plants can consume.

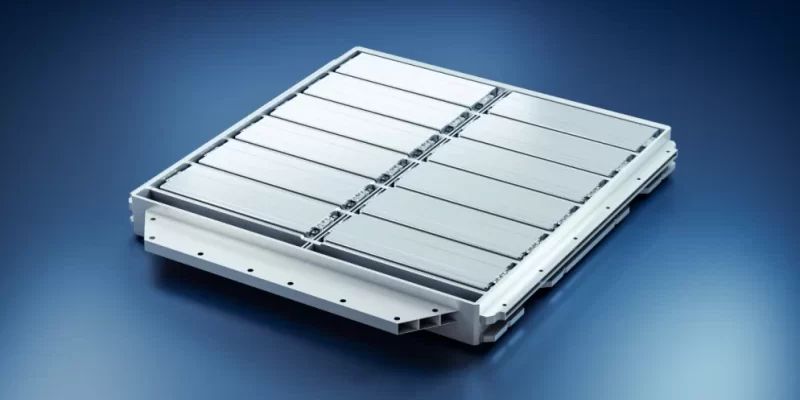

This assists with root development and plant maturation in agricultural settings. When it’s not being used for this purpose, phosphate rock is used to create purified phosphoric acid (PPA), which is then heated with iron and lithium salts. The resulting LFP ultimately finds its way into EV and solar panel battery packs.

Phosphate mining leaders have warned that a mineral shortage could threaten the LFP market as early as 2026. Only 10% of the world’s phosphate rock deposits are used to create PPA, resulting in a restricted supply for the growing EV and solar energy markets.

“There’s no way the current producers of PPA can keep up without new feedstock,” First Phosphate CEO John Passalacqua told Mining.com last month. “And in order to make a lot of purified phosphoric acid, that feedstock has to be igneous rock. A possible shortage could start by 2026 and get really bad by 2028.”

The deposit found in Norway is expected to ease these concerns while impacting the environment less than that imported from Asia.

“The phosphorus from China, Vietnam, or Kazakhstan doesn’t make a solar panel necessarily a green product,” Norge Mining founder Michael Wurmser told Euractiv, referring to the three countries’ relative lack of environmental standards for mining.

“So that underlines our concept that sustainability begins in the ground when you dig stuff out.” Reducing the need to import material from Asia will also bring down phosphate’s carbon emissions.

Norge Mining is now obtaining the necessary mining permits to bring the massive cache to production. Although the Norwegian government has reportedly agreed to fast-track raw material projects within the country, Norge Mining must provide economic viability and safety statements before the next phase can begin.

SOURCE:extremetech.com