A Pilbara miner is trying to harness renewable energy to reduce carbon emissions from the very lithium it produces for products such as electric vehicle batteries.

The region may be known as the world’s iron ore capital, but it’s also rich in minerals critical to renewable energy technology and battery production, including lithium.

This week, major lithium miner Pilbara Minerals announced a final investment decision (FID) for a joint-venture pilot processing facility with environmental technology company Calix Limited.

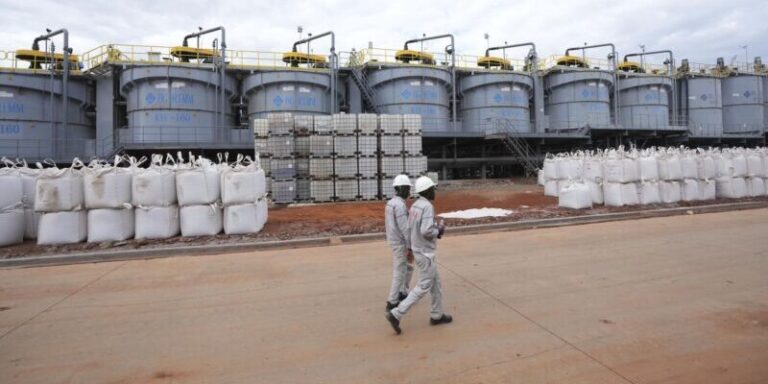

The $100 million demonstration plant will produce 3,000 tonnes of lithium phosphate from 27,000 tonnes of spodumene on site at Pilgangoora, south of Port Hedland.

Spodumene is a mineral that contains lithium which can be processed into lithium phosphate which is then used in the production of EV batteries.

The head of Pilbara Minerals, Dale Henderson, said the processing plant showed strong promise for the industry and local community.

“It has the potential, we think, to be a great step forward for … the industry,” he said.

“Adding more value to our spodumene concentrate to produce a different lithium product for market, and doing it through more sustainable methods — we think it’s really neat.”

Last year Western Australia’s lithium industry employed more than 3,300 workers, an increase of more than 80 per cent on the year prior.

Mr Henderson said Pilbara Minerals had agreements in place with Nyamal traditional owners with the mid-stream facility, as well as general operations at Pilgangoora.

He said the company worked with Nyamal entities “where possible”.

“The more we can do to do value-adding onshore within Australia is a good step forward for the community and all stakeholders,” Mr Henderson said.

“It’s about leveraging the incredible natural resource Australia has and making the most of that opportunity.

“If we can get that right, that absolutely flows through to the local community.”

Low-emission option

The Pilgangoora mid-stream processing pilot facility will be powered by a mix of renewable energy and conventional gas.

But Calix chief executive Phil Hodgson said its technology had the potential to be entirely renewables-driven.

“That’s what’s really exciting about this project — we’re combining this technology which is able to be renewably powered with Pilbara [Minerals] … to target this lithium phosphate salt,” he said.

“It’s onshoring jobs and value here … and we’re doing it in a renewable way.”

According to Calix Limited, its technology is 90 per cent less carbon intensive compared to traditional methods.

Battery material processing ‘very important’

Last year, 97 per cent of WA’s lithium was exported to China, with total exports worth more than $12 billion.

Moving away from Australia’s “dig-it-and-ship-it” mentality will be an important development for Australia, according to mining industry analysts.

It will also be vital in reducing Australia’s economic reliance on China, according to China business and resources expert Philip Kirchlechner.

“It would be wise [for Australia] to wean itself off dependence on China,” he said.

“I think it’s very important to put in place policies and make efforts in terms of geographical diversification, but also business diversification and business sector diversification.

“We need to transition from a purely primary industry excavating minerals to more processing, and then moving into more high-tech sectors such as battery [production].”

Construction was expected to begin on the mid-stream demonstration lithium phosphate plant imminently, with commissioning of the plant slated for late 2024.

If the pilot plant is a success, a full-scale plant will be proposed.