HPY Technology says it has provided a customised ore sorting solution to Zhicun Lithium, assisting the company in achieving efficient and environmentally friendly pre-concentration of its spodumene-based orebody, saving energy and reducing carbon emissions during the mineral processing process.

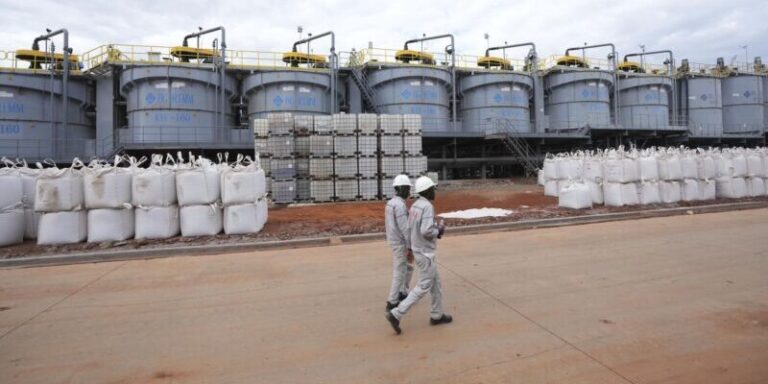

Located in Yichun City, Jiangxi Province, Zhicun Lithium has large-scale production capabilities when it comes to battery-grade lithium carbonate, lithium hydroxide and rubidium cesium salts from lithium resources.

According to 2021 data from the Asia Metal Website, Zhicun Lithium topped the national production in terms of battery-grade lithium carbonate. It has a projected output of 200,000 t/y in 2023.

HPY Technology, meanwhile, holds an 80% domestic market share in China and services over 100 mining customers worldwide, the company says.

It specializes in developing and manufacturing sensor-based ore sorting machines.

In late 2022, as part of its expansion project, Zhicun Lithium enlisted HPY Technology to develop an efficient lithium ore sorting solution.

The team tested ore samples provided by Zhicun, which were determined to be granite pegmatite spodumene.

Using these insights and considering the ore properties and on-site production volume, the Insight Series ore sorting machine was deployed for pre-concentration and waste removal testing.

The use of sensor-based sorting technology, HPY Technology says, provides a way to accurately distinguish ore from waste rock by measuring properties such as colour, texture and density.

This technological application not only enhances mining efficiency but also significantly reduces the environmental impact of mining activities by reducing waste and the inflow of tailings into the tailings pond, according to the company.

The Insight Series, equipped with VIS HD dual-sided imaging, X-ray imaging, laser imaging and more, allows detection methods to be combined freely depending on various mine characteristics, costs and benefits.

HPY Technology claims it offers the best detection combination solution based on the customer’s mine mineralisation properties.

The machines also leverage a multi-dimensional AI algorithm for fast image acquisition and high-resolution imagery, alongside time delay integration technology to avoid image distortion, offering a solid resistance to imaging interference.

The technology underwent a rigorous testing phase, first at the HPY testing centre, then at the mine site. The HPY engineering team provided swift and effective support throughout this phase, helping to achieve remarkable results that meet Zhicun Lithium’s technical specifications, it said.

With HPY Technology’s ore sorting machine, the results demonstrated a significant increase in ore grade, reaching over 2.5% Li2O, and an enrichment ratio exceeding two times.

Zhicun Lithium Group Co., Ltd. ore sorting results

Particle size: +10-60 mm

Processing capacity: 40-60 t/h

Raw ore grade: 1.27% Li2O

Waste rock grade: 0.6% Li2O

Concentrated ore grade: 2.63% Li2O

Rejection rate: 67%

Recovery rate: 68.35%

Enrichment ratio: 2.07

In 2023, HPY Technology plans to extend the use of the Insight Series to two more mining projects: one in a molybdenum mine in Luoyang, China, and the other in a gold mine in Tajikistan.

The company concluded: “This indicates a promising future for HPY Technology’s sensor-based ore sorting solutions, contributing to increased mining efficiency and sustainability.”